Manual or pneumatic operation, specifically for sanitary and aseptic processes in the pharmaceutical industry. This valve is ideal for fluid control and on/off tasks. The diaphragm provides a body seal and a seat seal. There is no path to the outside environment, so the diaphragm valve is suitable for aseptic processes. When the valve is closed, the pressure pad supporting the diaphragm moves toward the sealing surface on the valve body. As the pressure plate moves, the diaphragm bends and is forced to the seat area in the center of the valve body, thus closing the fluid path to the valve body. The relationship between the valve body and the pressure plate prevents the compression of the diaphragm. The valve can be operated manually or pneumatically, or it can be controlled by a controller and solenoid valve.

Specifications: 1' ~ 4‘’, DN25 ~ DN100

Pressure: 10bar (145 PSI)

Material: ASTM 316L, 1.4404, 1.4435 NB2 Fe<0.5%

Temperature: -20°C ~ +150°C (EPDM)-4°F+302°F (+140°C (SIP, 30) 284°F)

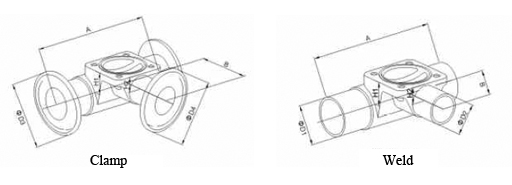

Connection: clamp, welding, thread, 3A BPE DIN SMS IDF ISO

Valve body structure: three-way, U-shaped three-way

Diaphragm material: EPDM + PTFE (double layer) / EPDM / Silicon / FPM (Vitong)

Certification: 3A-54-02/1580, PED 97/23 EC, FDA177.2600

Weld / Clamp 3A

|

Size |

D1 |

D2 |

D3 |

D4 |

A |

B |

H1 |

H2 |

|

1' - 1/2' |

25.4 |

12.7 |

50.5 |

25.4 |

100 |

59 |

24.5 |

9 |

|

1' - 3/4' |

19.1 |

25.4 |

59 |

24.5 |

13 |

|||

|

1' - 1' |

25.4 |

50.5 |

124 |

85 |

29.8 |

17 |

||

|

1 1/4' - 1/2' |

31.8 |

12.7 |

50.5 |

25.4 |

100 |

61 |

26.5 |

9 |

|

1 1/4' - 3/4' |

19.1 |

25.4 |

61 |

26.5 |

13 |

|||

|

1 1/4' - 1' |

25.4 |

50.5 |

124 |

85 |

32.8 |

17 |

||

|

1 1/4' - 1 1/4' |

31.8 |

50.5 |

85 |

32.8 |

20 |

|||

|

1 1/2' - 1/2' |

38 |

12.7 |

50.5 |

25.4 |

100 |

54 |

29.5 |

9 |

|

1 1/2' - 3/4' |

19.1 |

25.4 |

54 |

29.5 |

13 |

|||

|

1 1/2' - 1' |

25.4 |

50.5 |

124 |

89 |

35.8 |

17 |

||

|

1 1/2' - 1 1/4' |

31.8 |

50.5 |

152 |

109 |

35.8 |

20 |

||

|

1 1/2' - 1 1/2' |

38.1 |

50.5 |

109 |

35.8 |

23 |

|||

|

2' - 1 /2' |

50.8 |

12.7 |

64 |

25.4 |

100 |

70 |

33.5 |

9 |

|

2' - 3/4' |

19.1 |

25.4 |

70 |

33.5 |

13 |

|||

|

2' - 1' |

25.4 |

50.5 |

124 |

95 |

41.8 |

17 |

||

|

2' - 1 1/4' |

31.8 |

50.5 |

152 |

115 |

43.8 |

20 |

||

|

2' - 1 1/2' |

38.1 |

50.5 |

115 |

43.8 |

23 |

|||

|

2' - 2' |

50.8 |

64 |

184 |

123 |

43.3 |

29 |

Weld / Clamp DIN

|

Size |

D1 |

D2 |

D3 |

D4 |

A |

B |

H1 |

H2 |

|

DN25 - 1/2' |

28 |

12.7 |

50.5 |

25.4 |

100 |

59 |

24.5 |

9 |

|

DN25 - 3/4' |

19 |

34 |

59 |

24.5 |

13 |

|||

|

DN25 - DN20 |

22 |

34 |

85 |

24.5 |

13 |

|||

|

DN25 - DN25 |

28 |

50.5 |

124 |

85 |

29.8 |

17 |

||

|

DN32 - 1/2' |

34 |

12.7 |

50.5 |

25.4 |

100 |

61 |

26.5 |

9 |

|

DN32 - 3/4' |

19 |

25.4 |

61 |

26.5 |

13 |

|||

|

DN32 - DN20 |

22 |

34 |

61 |

26.5 |

13 |

|||

|

DN32 - DN25 |

28 |

50.5 |

124 |

85 |

32.8 |

17 |

||

|

DN32 - DN32 |

34 |

50.5 |

85 |

32.8 |

20 |

|||

|

DN40 - 1/2' |

40 |

12.7 |

50.5 |

25.4 |

100 |

64 |

29.5 |

9 |

|

DN40 - 3/4' |

19 |

25.4 |

64 |

29.5 |

13 |

|||

|

DN40 - DN20 |

22 |

34 |

64 |

29.5 |

13 |

|||

|

DN40 - DN25 |

28 |

50.5 |

124 |

89 |

35.8 |

17 |

||

|

DN40 - DN32 |

34 |

50.5 |

152 |

109 |

35.8 |

20 |

||

|

DN40 - DN40 |

40 |

50.5 |

109 |

35.8 |

23 |

|||

|

DN50 - 1/2' |

52 |

12.7 |

64 |

25.4 |

100 |

70 |

33.5 |

9 |

|

DN50 - 3/4' |

19 |

25.4 |

70 |

33.5 |

13 |

|||

|

DN50 - DN20 |

22 |

34 |

70 |

33.5 |

13 |

|||

|

DN50 - DN25 |

28 |

50.5 |

124 |

95 |

41.8 |

17 |

||

|

DN50 - DN32 |

34 |

50.5 |

152 |

115 |

43.8 |

20 |

||

|

DN50 - DN40 |

40 |

50.5 |

115 |

43.8 |

23 |

|||

|

DN50 - DN50 |

52 |

64 |

184 |

123 |

43.3 |

29 |

Contact: Mask

Phone: +86 15801773163

Tel: +86 21-66168818

Email: sales@f-fluid.com

Add: Xuhui District, Shanghai, China