The tank bottom ball valve is used for pressure vessels and storage tanks of draining and discharging with the fully inclusive designed ball seat and compensation automatic type sealing . So it has advantage of high pressure, high temperature resistance, small torque, long life and other characteristics to meet CIP and SIP cleaning and sterilization. It is very suitable for the application in high cleanliness requirements in process systems such as pharmaceutical, food and beverage, dairy products, chemical industry etc..

Pneumatic tank bottom ball valve can configure a variety of different actuators, electric, pneumatic and manual are interchangeable.

Size: DN25 ~ DN100, 1' ~ 4'

Pressure: 0 ~ 10bar

Material: ASTM 304 / 316L

Sealing material: PTFE, according to FDA

Working temperature: -30℃ ~ +130℃

Operating torque is small

Excretable

No matter what the flow fluid is, the handle can be mounted on the side of the valve body

No matter what kind of connection is, the valve can be replaced, without change the length of valve

Connection: Thread, Flange, Welding, Clamp, etc.

Operation Standard: DIN, SMS, RJT, 3A, ISO, IDF, BPE

Operation: Manually handle, electric pneumatic, stainless steel pneumatic, horizontal vertical pneumatic

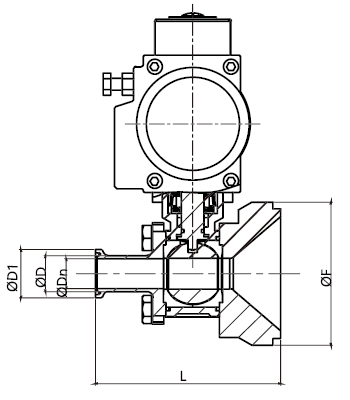

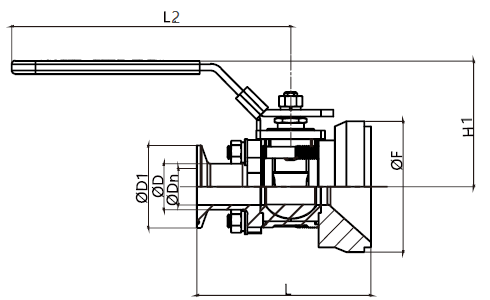

DIN Standard Weld / Clamp

|

Size |

Dn |

D |

K*K |

D1 |

L |

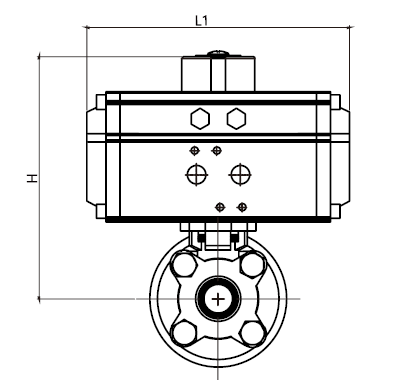

L1 |

L2 |

H1 |

H |

F |

|

DN25 |

25 |

28 |

11*11 |

50.5 |

106 |

155 |

170 |

78 |

114.5 |

120 |

|

DN40 |

37 |

40 |

14*14 |

50.5 |

125 |

168 |

173 |

98 |

177.5 |

120 |

|

DN50 |

49 |

52 |

14*14 |

64 |

140 |

219 |

173 |

107 |

202 |

150 |

|

DN65 |

66 |

70 |

14*14 |

91 |

155 |

249 |

223 |

151 |

230 |

180 |

|

DN80 |

81 |

85 |

17*17 |

106 |

176 |

274 |

335 |

160 |

258 |

212 |

|

DN100 |

100 |

104 |

17*17 |

119 |

210 |

315 |

335 |

169 |

292.5 |

248 |

3A Standard Weld / Clamp

|

Size |

Dn |

D |

K*K |

D1 |

L |

L1 |

L2 |

H1 |

H |

F |

|

1' |

22.1 |

25.4 |

11*11 |

50.5 |

106 |

155 |

170 |

78 |

114.5 |

120 |

|

1 1/2' |

34.8 |

38.1 |

14*14 |

50.5 |

125 |

168 |

173 |

98 |

177.5 |

120 |

|

2' |

47.5 |

50.8 |

14*14 |

64 |

140 |

219 |

173 |

107 |

202 |

150 |

|

2 1/2' |

60.2 |

63.5 |

14*14 |

77.5 |

155 |

249 |

223 |

130 |

230 |

180 |

|

3' |

72.9 |

76.2 |

17*17 |

91 |

176 |

274 |

335 |

153 |

258 |

212 |

|

4' |

97.4 |

101.6 |

17*17 |

119 |

210 |

315 |

335 |

169 |

292.5 |

248 |

Contact: Mask

Phone: +86 15801773163

Tel: +86 21-66168818

Email: sales@f-fluid.com

Add: Xuhui District, Shanghai, China